Air Mixers

Product Details:

- Technics requirement based

- Flow Rate requirement based

- Product Type Air Mixers

- Material Steel

- Metal Type Color Steel

- Application Industrial

- Size requirement based

- Click to view more

Air Mixers Price And Quantity

- 1 Piece

Air Mixers Product Specifications

- requirement based

- Color Steel

- requirement based

- requirement based

- Steel

- Air Mixers

- Industrial

- requirement based Pound (lb)

Air Mixers Trade Information

- seller responsiblity

- Cash in Advance (CID)

- 100 Piece Per Week

- 1 Week

- Sample costs shipping and taxes has to be paid by the buyer

- poly pack

- Asia

- All India

Product Description

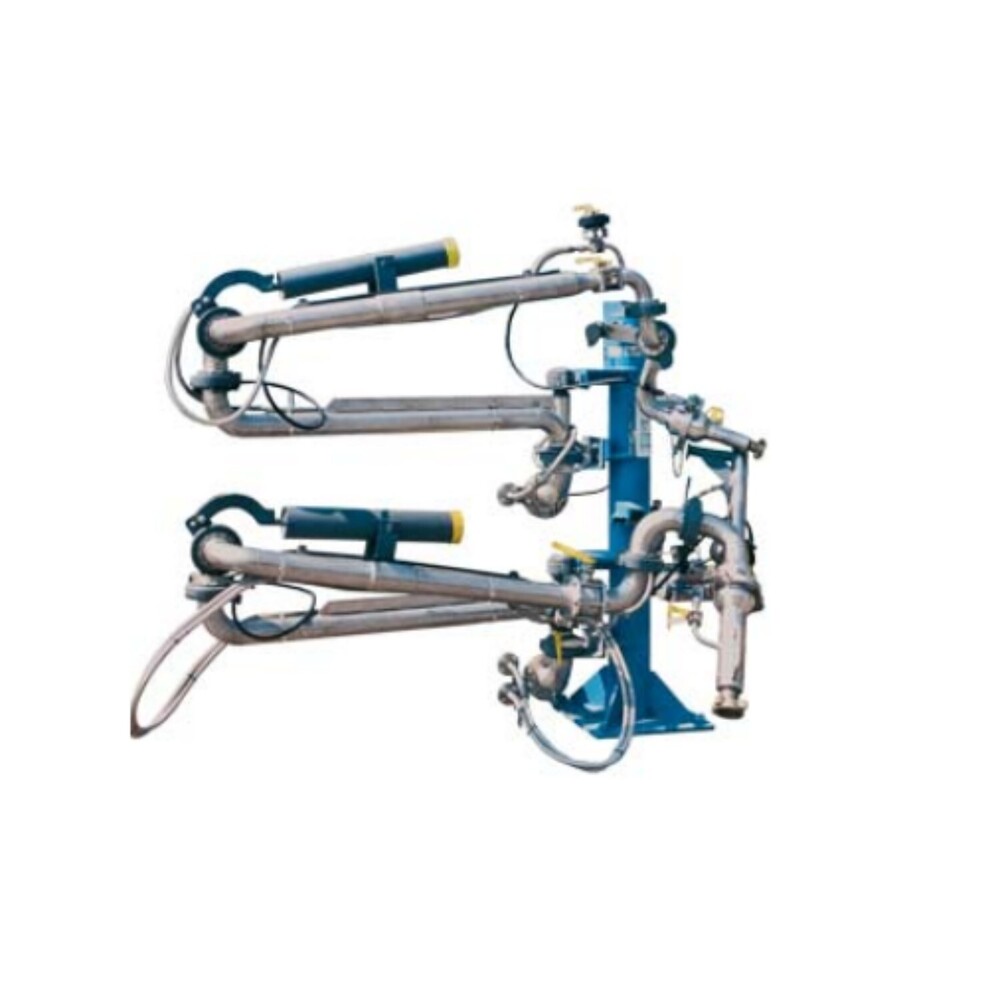

We are counted amongst the leading manufacturers, exporters and suppliers of excellent quality Air Mixers that are suitable for mixing air. These mixers are used as stand-by system for replacement of natural gas and peak shaving for base load applications. Available in varied specifications as per the needs of the customers, these mixers can be installed introducing gaseous fuel to the induction air of the engine. Can be used for gas delivery pressure up to 15 psig. max, offered mixers are easy to operate and switched on and off. Further, these Air Mixers are manufactured by our adroit professionals using supreme class raw material as per the set industry norms.

We are engaged in offering our clients an excellent range of Air Mixers that offers an intrinsically safe alternative in high solvent environments. The equipment uses compressed air to power mixing in tanks and drums. Available for clients in varied specifications to meet their individual requirements, these mixers are easy to operate and maintain. Sturdy in design, these are appreciated for their abrasion & wear resistance and consistent performance.

Features:

-

High performance

-

Sturdy construction

-

Durable finish standards

-

Excellent efficiency

Specifications:

- OGPE is proud to be associated with M/s. Algas-SDI (USA) for its entire range of products, which includes Synthetic Natural Gas System (LPG - Air Mixers), high-capacity Electrical Water/Steam Vaporizers, Stabilaire, Calorimeters and LPG Pressure Boosting System etc.

- LPG Air Mixing Systems are commonly used as stand-by system for the replacement of Natural Gas and Peak Shaving for applications of base load. Some of the Models have an integrated LPG Air Mixing System and Vaporizer. There are mainly two designs of LPG-Air Mixing System.

- LPG Air Mixing System type: Vaporaire and Blendaires Vaporaire is a Venturi type LPG Air Mixer, which is used for delivery of gas pressure upto 15 Psig, max. The Equipment performs on a Venturi design, through which LPG vapours enter at a high pressure making vacuum and thereby sucking in air from the atmosphere to provide desired diluted gas. There is a solid state sequencer which automatically switches different arms of the unit, taking action from pressure transducer. It is an easy to install system requires negligible maintenance, if properly installed.

Product details

|

Capacities Range |

4 M Kcal/Hr. to 220 M Kcal/hr. |

|

Compatible mix pressure |

10 Psig |

|

Power |

Electric |

|

Product Type |

Elevators |

|

Usage |

Air Pump |

|

Warranty |

12 Months |

Precision Engineering for Industrial Needs

Our air mixers offer unmatched durability and versatility, with every unit designed and manufactured based on your specific requirements. Whether you need a custom weight, flow rate, or size, our expert team leverages specialized technics for optimal performance across diverse industries.

Comprehensive Solutions for Every Client

We cater to a broad spectrum of rolesdistributor, exporter, importer, manufacturer, service provider, supplier, or traderensuring seamless access and support for our industrial air mixers throughout India. This all-encompassing approach guarantees clients benefit from technical expertise, fast delivery, and after-sales assistance.

FAQs of Air Mixers:

Q: How can the weight and size of the air mixer be specified for my application?

A: The air mixers we provide are based on requirement-driven design, allowing you to specify the precise weight in pounds and the desired size to fit your industrial application. Our team will assist in evaluating your process needs and recommend the most suitable configuration.Q: What is the typical process for ordering an industrial air mixer from your company in India?

A: To order an air mixer, you can contact us with your application details, including desired weight, flow rate, and size. Our experienced staff will guide you through product selection, customization, quotation, and delivery, providing end-to-end support as per the industrial requirements.Q: Where are these air mixers mainly used?

A: Our air mixers are commonly deployed in a variety of industrial sectors such as chemical processing, pharmaceuticals, food manufacturing, and water treatment plants. Their construction from steel and color steel makes them ideal for rigorous operating conditions.Q: What benefits do steel and color steel air mixers offer over other materials?

A: Air mixers made from steel and color steel offer superior durability, corrosion resistance, and strength, making them well-suited for challenging industrial environments where reliability and longevity are essential.Q: How do I determine the correct flow rate requirement for my industrial process?

A: Our technical team will work with you to analyze your process parameters, including the type of material to be mixed, tank size, and throughput needs. This ensures the air mixer is configured to provide the optimal flow rate for effective mixing and productivity.Q: When should an air mixer be serviced or maintained?

A: Regular maintenance schedules are recommended based on operating hours and material type. We can provide guidelines and service support to help maintain peak mixer performance and maximize equipment lifespan.Q: What is the usage procedure for installing and operating your air mixers?

A: We supply detailed installation and operating manuals, along with optional on-site support for commissioning. Proper installation by following our guidelines ensures safe and efficient mixer operation in your facility.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+