High Differential Pressure Pumps

Product Details:

- Head Size requirement based

- Inlet/Outlet requirement based

- Mounting Type requirement based

- Features requirement based

- Caliber requirement based

- Discharge Pressure requirement based

- Flow Rate requirement based

- Click to view more

High Differential Pressure Pumps Price And Quantity

- 1 Piece

High Differential Pressure Pumps Product Specifications

- Water Well

- requirement based

- requirement based

- Blue

- requirement based

- requirement based

- High Pressure

- requirement based

- requirement based

- requirement based

- Differential Pressure Pumps

- requirement based

- requirement based

- requirement based

- requirement based

- requirement based

- requirement based

- Electric

- Metal

High Differential Pressure Pumps Trade Information

- requirement based

- 100 Piece Per Week

- 1 Week

- Sample costs shipping and taxes has to be paid by the buyer

- poly pack

- Australia, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia, North America

- All India

Product Description

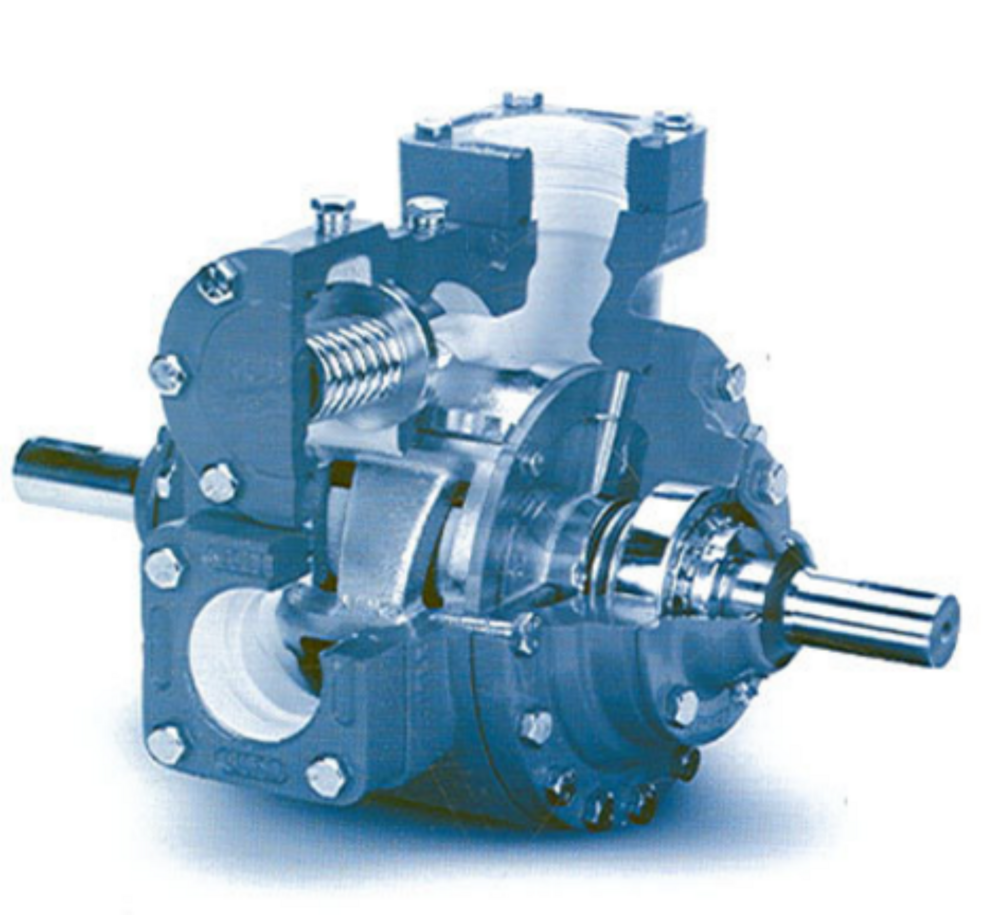

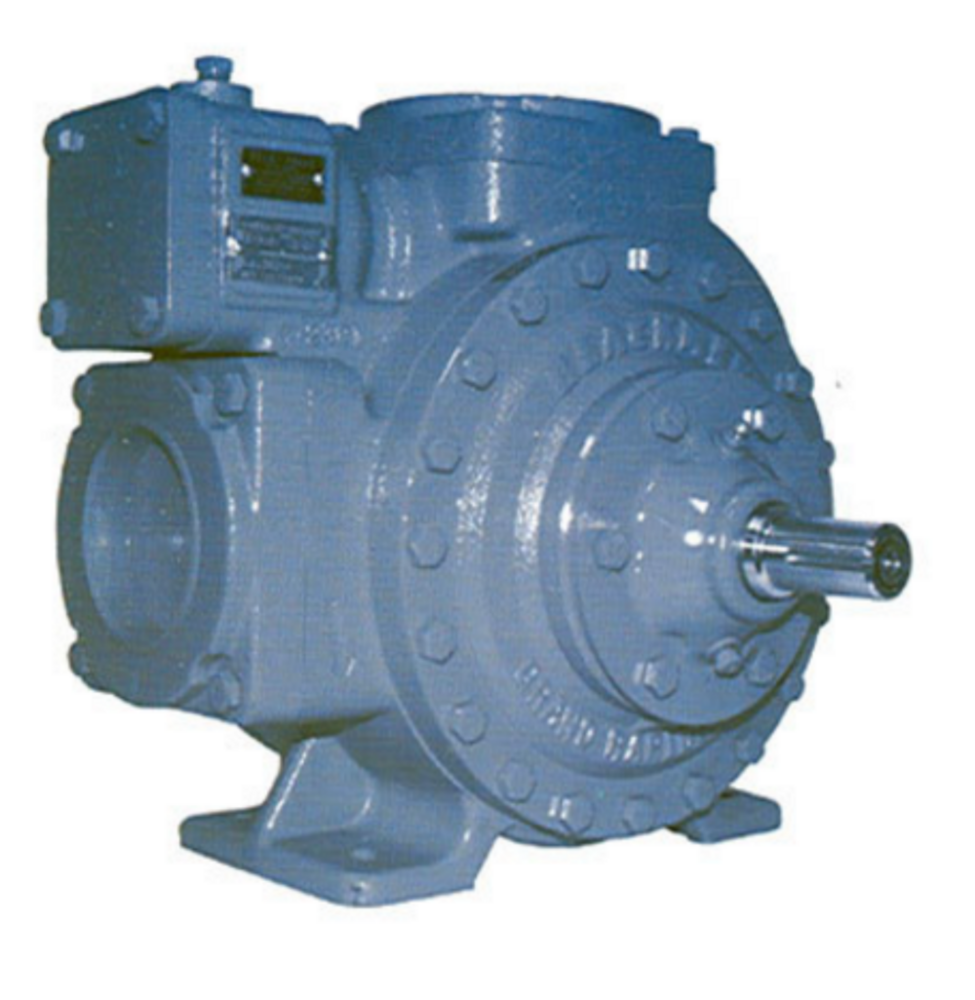

High Differential Pressure Pumps are designed with sliding vane in positive displacement design to ensure constant efficacy and performance. They are ideal to be used for high differential pressure of 13.7 bars. The motor speed operation of the pumps is at 1,450 rpm (50Hz) or 1,750 rpm (60Hz) operation. They are designed with LGL 158 suction lift up to 13 feet (4 meters) and LGL 154 & 156 models with single phase motors. In addition to this, they come with cavitation suppression liner, ductile iron design and replaceable liner and discs. With flanged inlet and outlet connections along with ISO-9001 certified design, they provide the best performance.

Applications:

- Single and dual hose fuel dispensers

- Aerosol filling

- Vaporizer feed

- Underground tank applications

- Aboveground tank applications

- Other high differential pressure liquefied gas applications

- U.L. listed for use on propane, butane and butane/propane mixes and anhydrous ammonia

Direct Motor Drive

Base mounted units are available, complete with pump, coupling and coupling guard, mounting on a common base, ready to accept a standard NEMA C- face or IEC flanged-face motor. DM units are available with and without electric motors.

Technical Specifications:

|

Pump Model |

Maximum Speed |

GPM (L/min) |

HP (kW) |

Maximum Differential Pressure |

Recommended Bypass Valve Setting |

Relief Valve Setting |

Maximum Working Pressure |

|

LGL154 |

1,750 |

11.2(42.4) |

3(2.2) |

140 PSI (9.6 bar) |

140 PSI (9.6 bar) |

225 PSI (15.5bar) |

425 PSI (29.3bar) |

|

LGL156 |

1,750 |

21(79.5) |

4.9(3.6) |

160 PSI (11.00bar) |

160 PSI (11.00bar) |

225 PSI (15.5bar) |

425 PSI (29.3bar) |

|

LGL158 |

1,750 |

32.3(122) |

6.5(4.8) |

200 PSI (13.8 bar) |

200 PSI (13.8 bar) |

225 PSI (15.5bar) |

425 PSI (29.3bar) |

Engineered for Versatility and Performance

Designed to meet different operational demands, High Differential Pressure Pumps adapt to various suction types, calibers, and flow rate requirements. With options for priming and mounting, these pumps seamlessly integrate into both water well and industrial systems, offering optimal customization. Their electric-powered metal construction assures durability, while variable control systems keep operation precise and efficient.

Comprehensive Supply Network Across India

As a product available from distributors, exporters, importers, manufacturers, and service providers, these pumps are accessible for partner businesses throughout India. The robust supply chain ensures timely delivery, technical support, and after-sales service, making them an ideal choice for both industrial and water well applications.

FAQs of High Differential Pressure Pumps:

Q: How do I select the right High Differential Pressure Pump for my specific application?

A: Selection depends on factors such as required discharge pressure, flow rate, suction type, and head size. Our team will guide you in determining the precise configuration based on your water well or industrial needs to ensure efficient and reliable performance.Q: What benefits do High Differential Pressure Pumps offer for water wells and industrial systems?

A: These pumps deliver consistent high-pressure performance, adaptable for a range of applications. Their robust metal construction, efficient electric operation, and customizable control systems provide long-term durability, energy savings, and seamless integration into existing setups.Q: When is it recommended to use a High Differential Pressure Pump?

A: Use these pumps when your process requires high discharge pressures, reliable handling of large flows, or if your system involves challenging suction and head conditions. They are ideal for deep water wells and complex industrial processes demanding precise pressure management.Q: Where can I purchase or inquire about these pumps in India?

A: High Differential Pressure Pumps are available through a network of distributors, manufacturers, suppliers, traders, and service providers across India. You can connect with us directly or through our authorized partners for consultations and procurement.Q: What is the process for installing and commissioning these pumps?

A: Installation involves evaluating site requirements, selecting suitable mounting and priming types, and ensuring proper alignment of inlets and outlets per the pumps design. Our technical team offers support throughout installation and commissioning for optimal setup and performance.Q: How is the pumps performance monitored and controlled?

A: Each pump can be equipped with a requirement-based control system, enabling real-time monitoring and automatic adjustment of operating parameters. This facilitates operational efficiency and safeguards against irregularities.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+