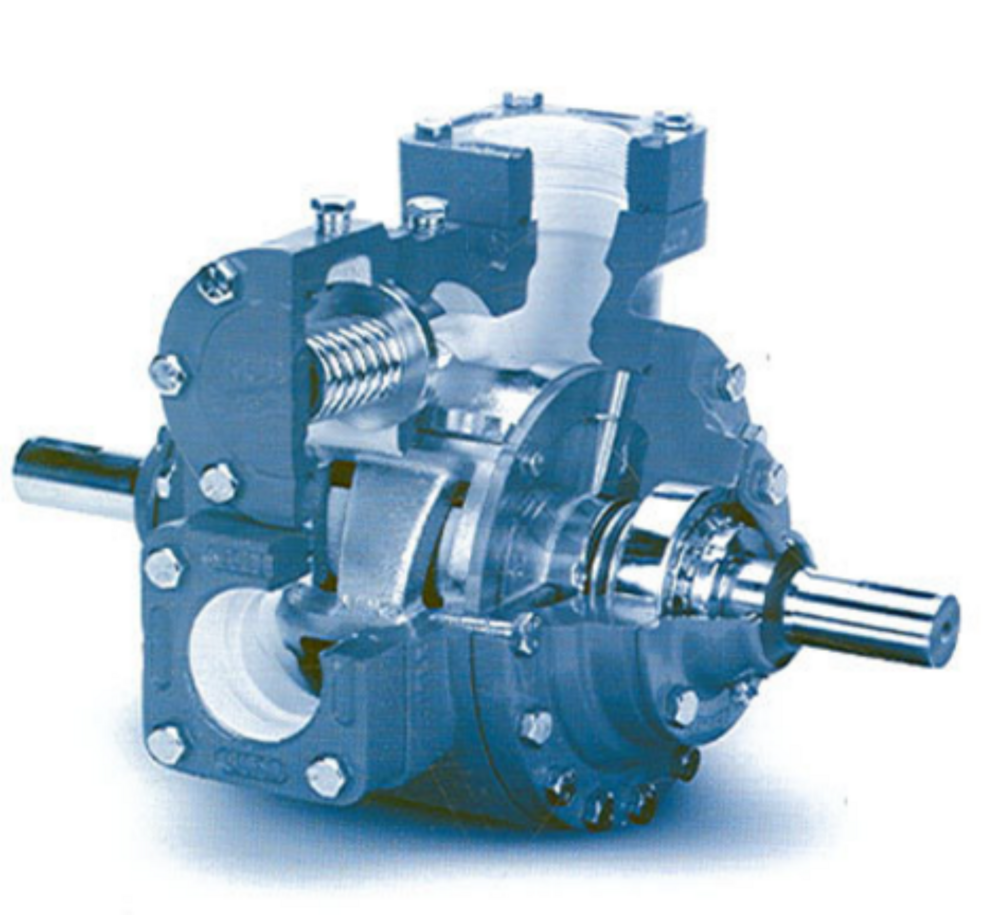

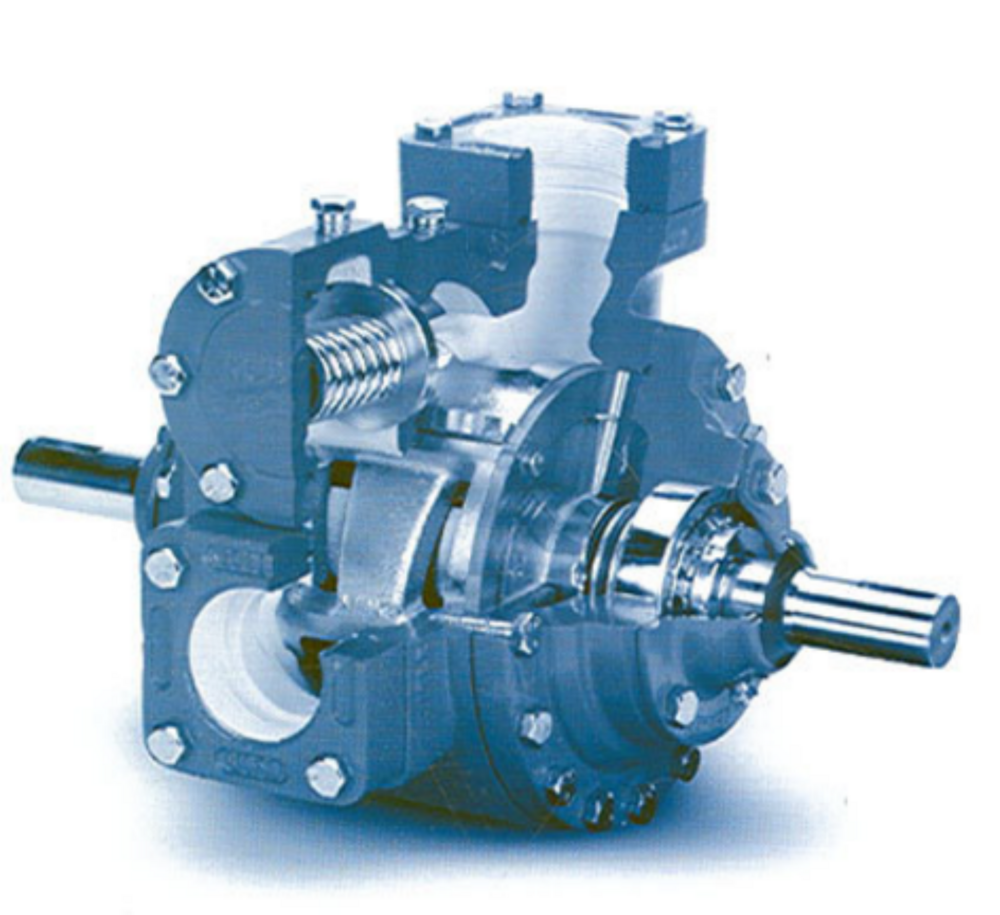

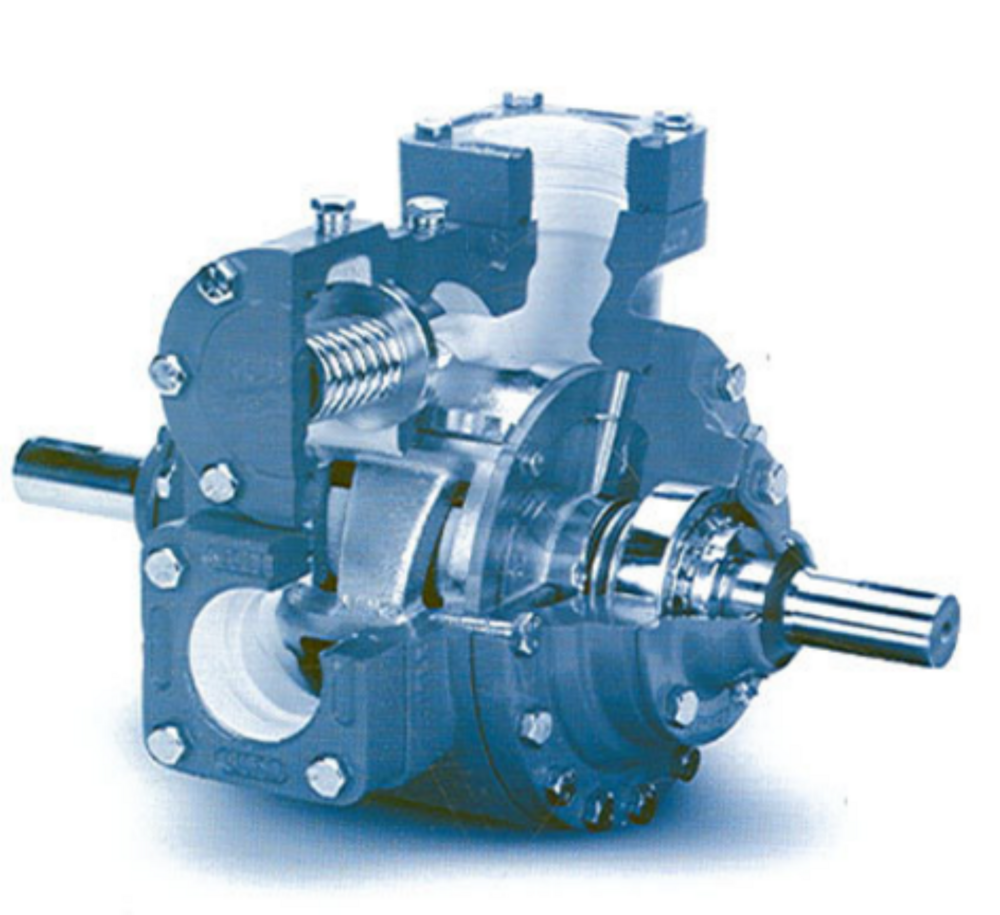

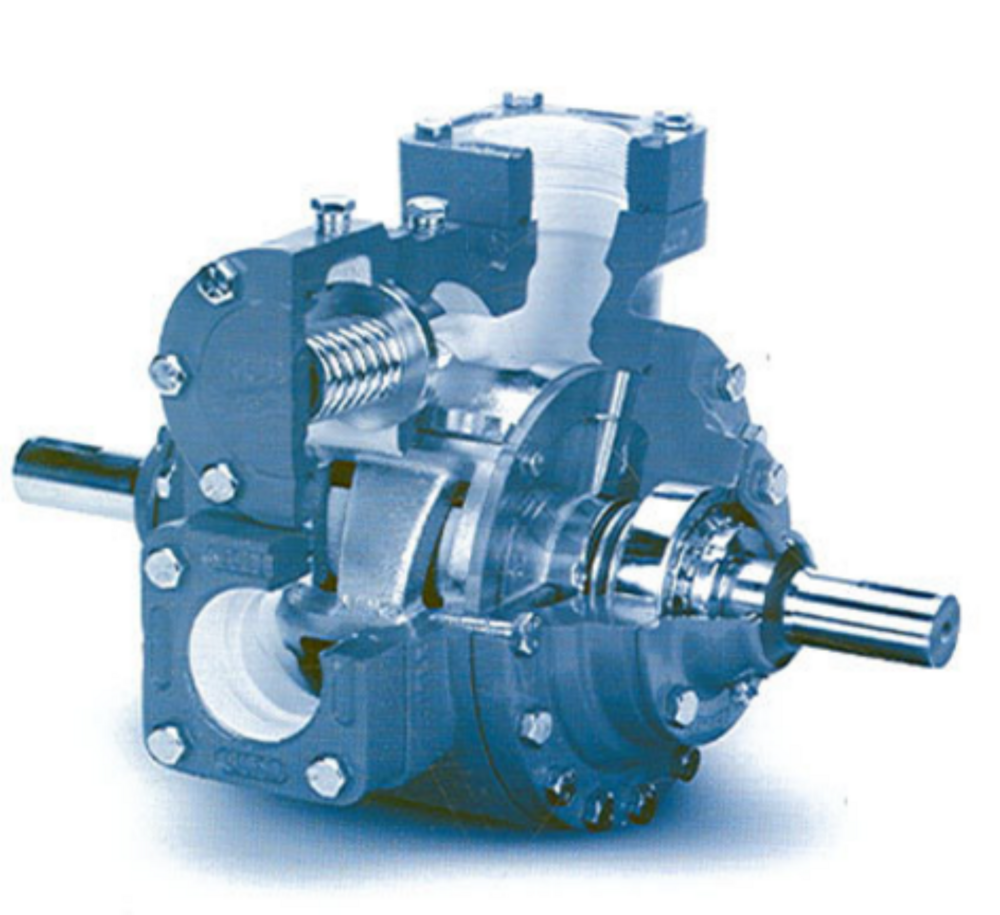

High Pressure Pump

Product Details:

- Head Size requirement based

- Discharge Pressure requirement based

- Flow Rate requirement based

- Max Suction requirement based

- Inlet/Outlet requirement based

- Caliber requirement based

- Usage Industrial

- Click to view more

High Pressure Pump Price And Quantity

- 1 Piece

High Pressure Pump Product Specifications

- requirement based

- requirement based

- requirement based

- Industrial

- High Pressure

- requirement based

- requirement based

- requirement based

- Metal

- Sewage, Submersible

- High Pressure Pump

- requirement based

- Electric Watt (w)

- requirement based

- requirement based

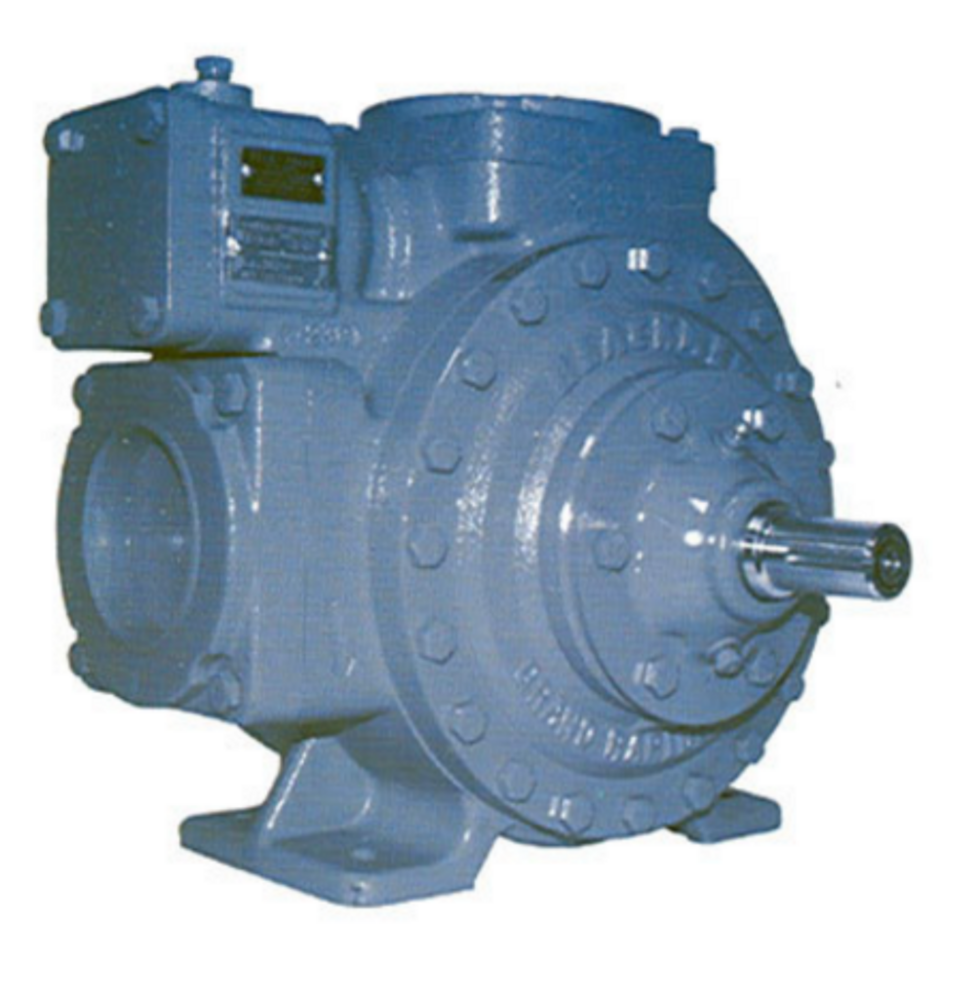

- Blue

- requirement based

High Pressure Pump Trade Information

- requirement based

- Cash in Advance (CID)

- 100 Piece Per Week

- 1 Week

- Sample costs shipping and taxes has to be paid by the buyer

- poly pack

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Asia, Central America, Africa

- All India

Product Description

- Designed for high differential pressure of 165 psi (11.4 bar)

- Sliding vane, positive displacement design for consistent performance

- Dimensionally interchangeable with the LGLD2

- Up to 980 rpm operation

- Patented 7cavitation suppression liner

- Replaceable liner and discs

- Ductile iron construction

- Flanged inlet and outlet connections

- Factory ISO-9001 certified

- High differential pressure bobtail delivery trucks

- High capacity LPG fueling

- Aerosol filling

- Vaporizer feed

- Other high differential pressure liquefied gas applications

- U.L. listed for use on propane, butane and butane/propane mixes

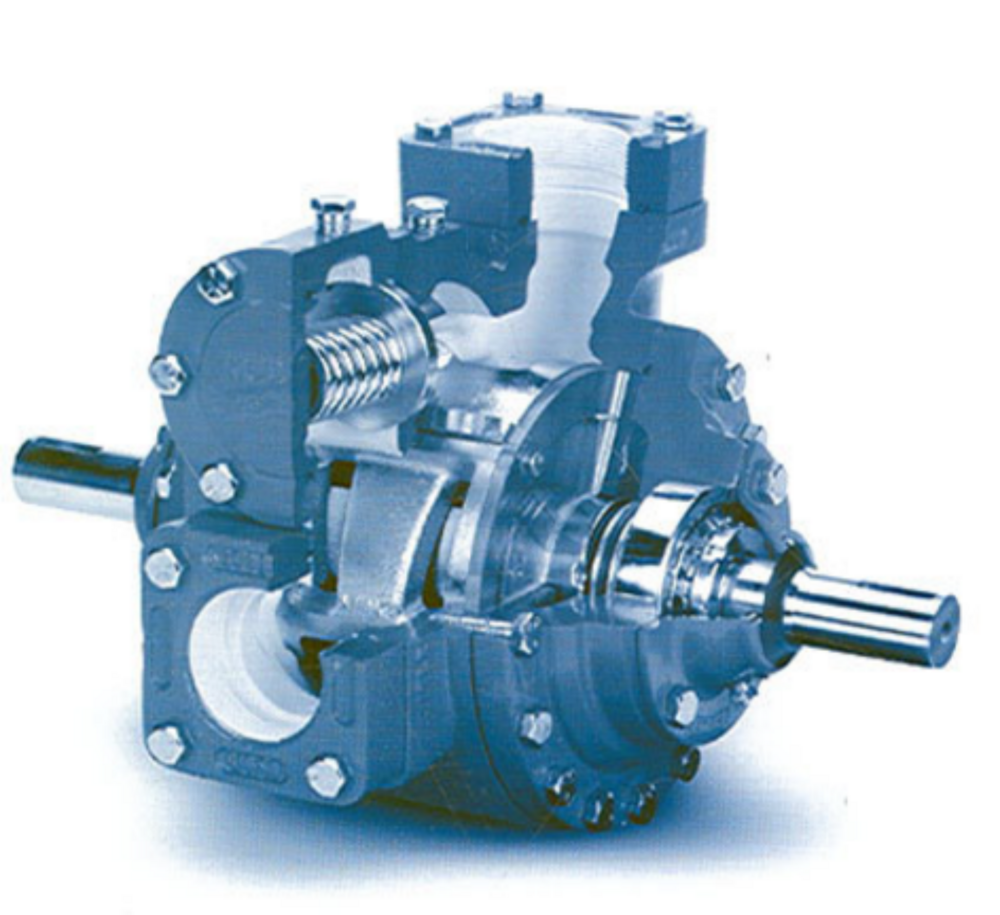

VB Drive Style

V-Belt Drive

Standard base-mounted VB units are available, complete with pump, hubs, sheaves, high-torque V-belts and belt guard, mounted on a common base, ready to accept a standard NEMA motor. All VB units are available with or without motors.

HR Drive Style

Helical Gear Reduction Drive

Standard base-mounted HR units are available, complete with pump, Blackmer Helical Gear Reducer, mounting brackets, couplings and coupling guards, mounted on a common base, ready to accept a standard NEMA motor. All HR units are available with or without motors.

Product details

|

Fuel Type |

- Petro chemicals - Gasoline - Biofuels - Solvents - and many more |

|

Feature |

Adjustable relief valve protects pump from excessive pressure. Optional air operated relief valve of |

|

Design |

Sliding Vane Pumps |

|

Capacity |

60 LPM |

|

Brand |

Blackmer |

|

I Deal In |

New Only |

Technical Specifications:

|

Performance at 145 psid (10 bar) Differential Pressure |

Maximum Differential Working |

Relief Valve Setting |

||

|

780rpm |

640rpm |

520 rpm |

||

|

61gpm / 11.7 hp |

47gpm / 9.2 hp |

32.6gpm / 7.1 hp |

165 psi |

190 psi |

|

231lpm / 8.7 kw |

178 lpm / 6.9 kw |

123 lpm / 5.3 kw |

11.4 bar |

13.1 bar |

Flexible Customization to Suit All Industrial Needs

Every parameter of our High Pressure Pumpfrom suction and size to pressure and flow rateis tailored to your exact specifications. Our versatile approach ensures you get precisely the capabilities you need for each unique application, whether its sewage management or submersible usage.

Metal Construction for Reliable Performance

Built with premium-quality metal, the pump resists wear and offers extended operating life. Its electric drive guarantees consistent, energy-efficient power delivery, even in challenging environments. This makes it ideal for continuous industrial operation.

FAQs of High Pressure Pump:

Q: How is the required specification determined for a high pressure pump?

A: Our technical team collaborates with you to assess your specific industrial requirementssuch as the needed suction, discharge pressure, flow rate, and application detailsensuring that the pump is custom-configured for optimal performance in your environment.Q: What industries commonly use this high pressure pump in India?

A: This pump is widely used in industries like sewage treatment, construction, municipal services, chemical processing, and water utilities, especially where high pressure and reliable, continuous operation are necessary.Q: When should I consider a submersible high pressure pump for sewage applications?

A: You should opt for a submersible high pressure pump when dealing with applications where the pump must operate underwater, such as in sewage pits or flooded locations, for efficient fluid transfer and minimal maintenance intervention.Q: Where can I install this high pressure pump for maximum efficiency?

A: Installation is typically recommended at sites with stable power supply and secure mounting. For sewage and submersible scenarios, ensure the site supports safe access, correct priming, and compatible inlet/outlet connections as per requirements.Q: What is the process for ordering a custom high pressure pump?

A: Simply contact our team with your detailed specificationssuch as head, flow rate, caliber, pressure rating, and application type. We guide you through selecting the optimal configuration, and manage production, inspection, and timely delivery.Q: How does this high pressure pump benefit sewage and submersible operations?

A: Its tailored design ensures efficient handling of high-pressure sewage transfer, reducing blockages and downtime. The robust sealing system and sturdy metal build withstand harsh waste environments, enhancing reliability and longevity.Q: What advantages does high pressure operation offer over standard pumps?

A: High pressure pumps move fluids quickly over long distances or through restrictive pipes, benefitting operations requiring swift sewage clearance or high-volume fluid managementminimizing process delays and operational costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+