Circulating Hot Water Vaporizer

Product Details:

- Product Type Circulating Hot Water Vaporizer

- Material nil

- Technics nil

- Metal Type Steel

- Application Industrial

- Size nil

- Weight nil Grams (g)

- Click to view more

Circulating Hot Water Vaporizer Price And Quantity

- 1 Piece

Circulating Hot Water Vaporizer Product Specifications

- Circulating Hot Water Vaporizer

- nil

- nil

- Industrial

- Steel

- nil

- nil Grams (g)

Circulating Hot Water Vaporizer Trade Information

- nil

- Cash in Advance (CID)

- 100 Piece Per Week

- 1 Week

- Sample costs shipping and taxes has to be paid by the buyer

- poly pack

- All India

Product Description

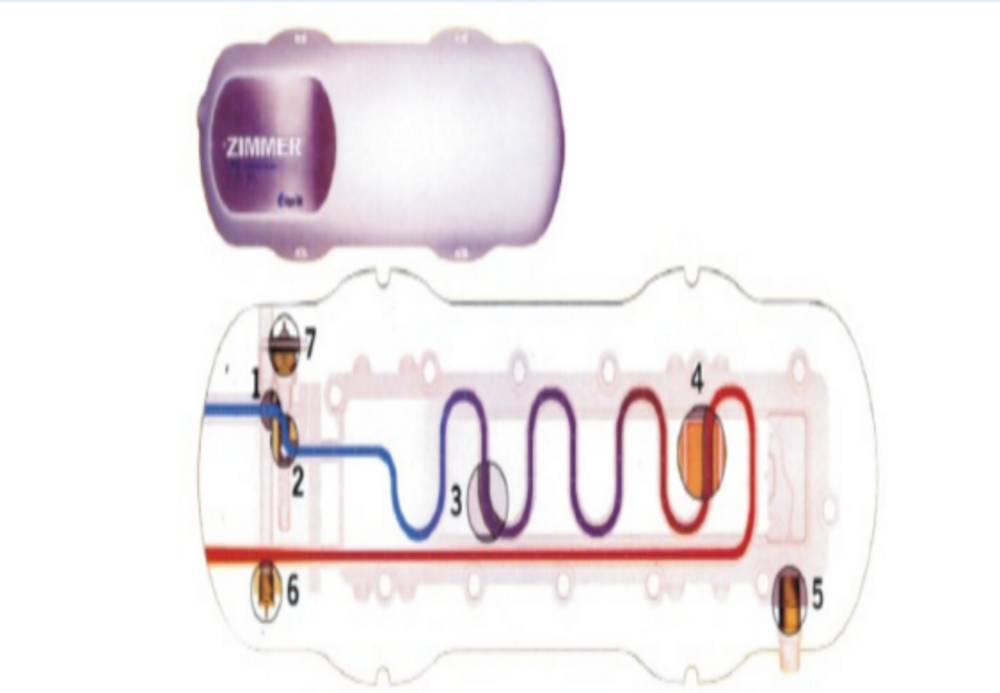

Leveraging on our vast industry experience, we are offering our clients a finest quality range of Circulating Hot Water Vaporizer that is used to vaporize cryogenic fluids. The manufacturing process of this vaporizer is carried out according to the set industry standards using best grade raw material with the help of latest technology. It can be used elsewhere in the plant and is added to an existing water system. Moreover, this Circulating Hot Water Vaporizer is available in various specifications as per the requirements to customers.

Circulating Hot Water Vaporizer is acknowledged for its 100% turn down capability. All the exposed metal parts in the vaporizer are mechanically cleaned, primed and painted for durability. These are manufactured by our skilled team using quality approved materials and modern techniques keeping in mind predefined industry standards. Apart from this, the product is available in various specifications to clients at nominal prices.

Features :

- 100% turn down capability.

- Both LPG and hot water fabrication are stamped in accordance with ASME.

- Explosion Proof configuration meets Class I, Division 1, Group D as defined by NFPA pamphlet 70.

- Factory Mutual (FM) approved.

- Two safety devices to ensure dry superheated vapor.

- Bayonet style tubes allow stress-free expansion unlike other designs.

- Fully insulated for maximum thermal efficiency.

- Ready to connect to plant facilities.

- Strainer included.

- Stainless steel outer heat exchanger tubes standard.

- LPG pressure vessel is fabricated in accordance with ASME Pressure Vessel Code, Section VIII, Division 1.

- LPG pressure vessel rating: 250 PSIG at 650? F (17.6 Kg/Cm2 at 343? C).

- U.L. stamped external relief valve: 250 PSIG (17.6 Kg/Cm2).

- Factory Mutual (FM) approved.

- All wiring, controls, electrical components and their installation comply with recognized code standards defined in NFPA pamphlet 58 and NFPA pamphlet 70.

- Explosion Proof configuration meets Class I, Division 1, Group D as defined by NFPA pamphlet 70.

- Pressure balanced LPG supply/delivery operation.

- Two safety devices to prevent liquid carryover -low vapor temperature switch and high liquid level switch.

- Inlet safety solenoid valve.

- All exposed metal surfaces are mechanically cleaned, primed and painted.

Product details

|

LPG pressure vessel rating |

250 PSIG at 650 F (17.6 Kg/Cm2 at 343 C). |

|

stamped external relief valve |

250 PSIG (17.6 Kg/Cm2) |

|

Turn down capability |

100% |

|

Automatic Grade |

Automatic |

|

Design |

Standard |

Robust Steel Construction

Our Circulating Hot Water Vaporizer is engineered with durable steel, ensuring longevity and resilience in demanding industrial conditions. This material choice provides excellent resistance to corrosion and mechanical stress, making the vaporizer a reliable component in your operations. Designed for performance, it helps maintain consistent output and minimizes downtime, supporting seamless industrial workflows.

Comprehensive Supply Chain in India

We operate as a distributor, exporter, importer, manufacturer, service provider, supplier, and trader throughout India. This extensive network guarantees prompt delivery, expert technical support, and swift after-sales service. Whether you require individual units or bulk orders, our team ensures trouble-free logistics and comprehensive assistance, meeting the needs of diverse industrial customers nationwide.

FAQs of Circulating Hot Water Vaporizer:

Q: How does a Circulating Hot Water Vaporizer function in industrial applications?

A: The Circulating Hot Water Vaporizer operates by heating water and circulating it to produce a controlled stream of hot water vapor. This vapor can be used for cleaning, processing, or humidification in various industrial processes, ensuring consistent temperature and moisture control.Q: What are the primary benefits of using a steel-constructed vaporizer?

A: Utilizing steel as the primary construction material provides robust durability, high resistance to corrosion, and long service life. These qualities ensure the vaporizer can withstand harsh industrial environments, reducing maintenance costs and downtime.Q: When should an industrial facility consider installing a Circulating Hot Water Vaporizer?

A: Installation is recommended when consistent and efficient hot water vapor generation is needed for industrial processes such as sterilization, cleaning, or moisture control. Facilities experiencing frequent heating inefficiencies or requiring large-scale vapor production will particularly benefit from this system.Q: Where are these vaporizers typically supplied or installed in India?

A: These vaporizers are distributed and installed throughout India by recognized manufacturers, suppliers, and service providers. They are commonly found in factories, processing plants, and large industrial facilities requiring regulated hot water vapor.Q: What is the general process for sourcing and installing this vaporizer in an industrial setting?

A: To procure a Circulating Hot Water Vaporizer, businesses can contact suppliers or manufacturers in India. The process includes product selection, customization if needed, delivery, professional installation by service providers, and technical support for optimal integration into the facilitys operations.Q: How is the vaporizer maintained to ensure efficient operation?

A: Routine maintenance involves periodic checking of the steel components for scaling or deposits, inspecting connections and heating elements, and ensuring the circulation system is free from blockages. Regular servicing by certified technicians helps in sustaining peak performance and longevity.Q: What industries benefit most from the use of this hot water vaporizer?

A: Industries such as pharmaceuticals, food processing, chemical manufacturing, and textile production benefit significantly from the consistent vapor output, enhanced control, and operational efficiency offered by a steel circulating hot water vaporizer.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+